VANCOUVER, British Columbia, Oct. 08, 2025 (GLOBE NEWSWIRE) -- K92 Mining Inc. (“K92” or the “Company”) (TSX: KNT; OTCQX: KNTNF) is pleased to announce production results for the third quarter (“Q3”) of 2025 from its Kainantu Gold Mine in Papua New Guinea.

Q3 2025 Production Results

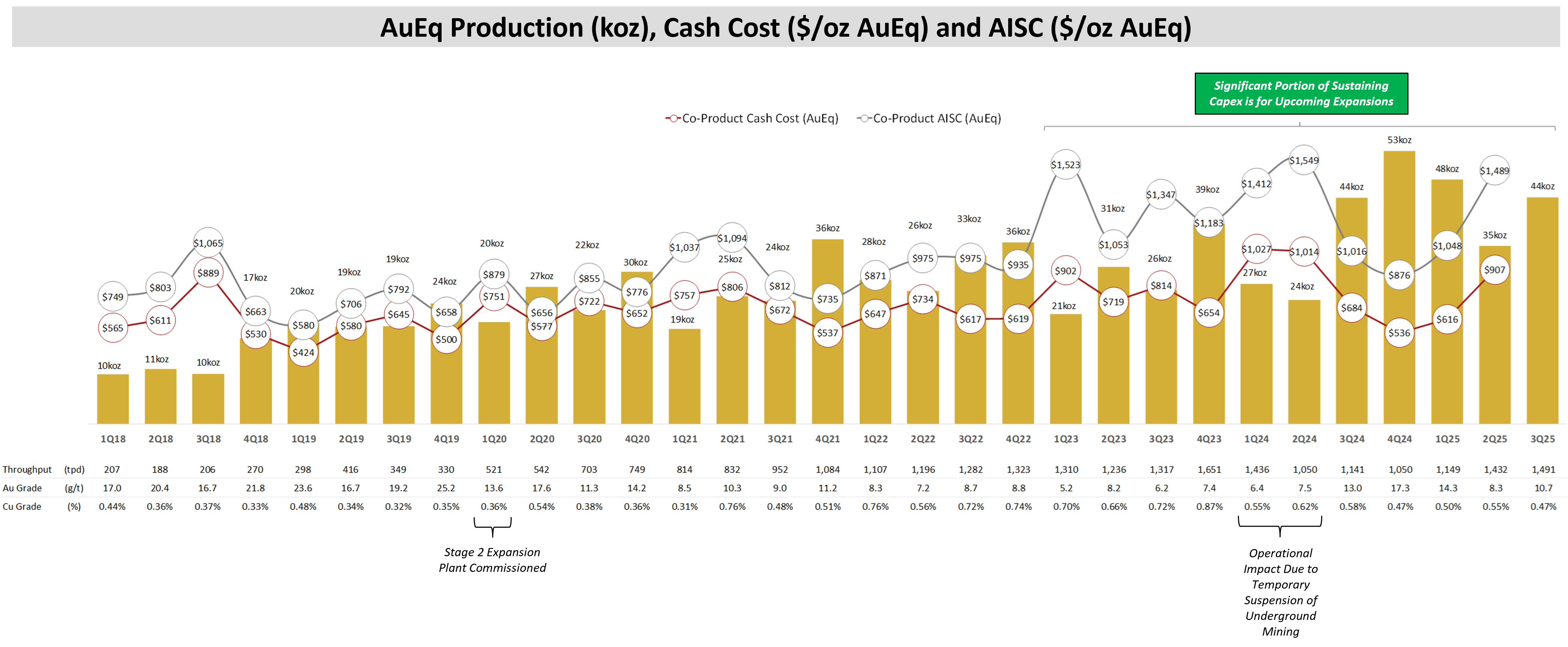

- Strong quarterly production of 44,323 ounces gold equivalent (“AuEq”)(1) or 42,244 oz gold, 1,323,538 lbs copper and 34,831 oz silver (Figure 1). Quarterly sales of 45,006 oz gold, 1,480,151 lbs copper and 43,271 oz silver. With more than 80% of the lower end of annual guidance achieved in the first three quarters, plus ending Q3 with a 4,893 oz AuEq commissioning stockpile in line with the Stage 3 Expansion requirements (28,702 tonnes at 5.3 g/t AuEq or 5.0 g/t gold, 0.24% copper, and 11.9 g/t silver), the Company remains on track to meet its 2025 production guidance of 160,000–185,000 oz AuEq.

- Quarterly ore processed of 137,172 tonnes, a 31% increase from Q3 2024, with a head grade of 11.2 grams per tonne (“g/t”) AuEq, or 10.7 g/t gold, 0.47% copper and 10.3 g/t silver. Head grade during the quarter was above budget, benefitting from a positive gold grade reconciliation versus the latest independent mineral resource estimate (September 12, 2023 effective date for Kora and Judd).

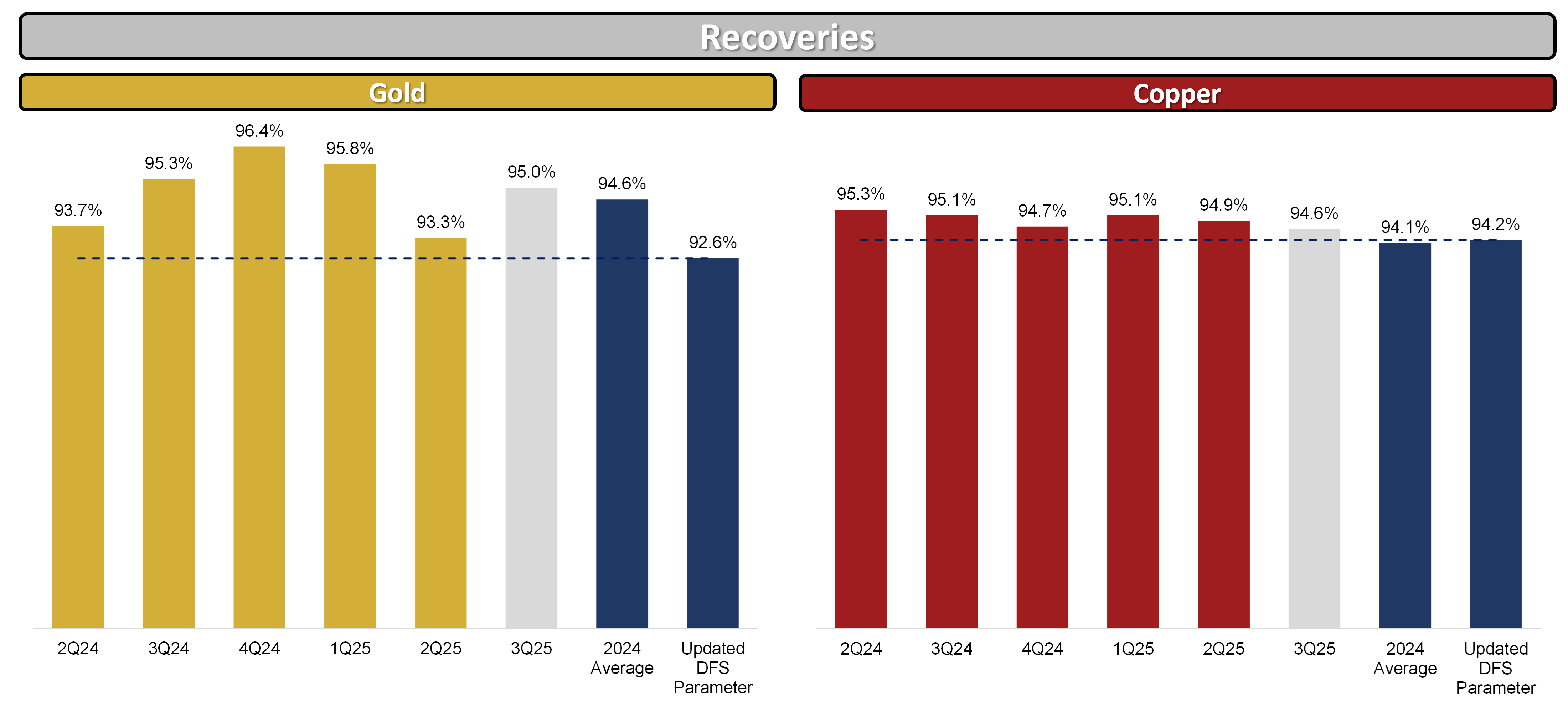

- Strong metallurgical recoveries in Q3 of 95.0% for gold and 94.6% for copper (Figure 2). The process plant has now delivered six consecutive quarters exceeding the updated definitive feasibility study (“Updated DFS”) recovery parameters for both gold (92.6%) and copper (94.2%) (January 1, 2024 effective date).

- Record total material mined (ore plus waste) of 353,770 tonnes, with multiple tonnes to surface daily records (ore plus waste) in late-September, including 5,769 tonnes on September 27 and 6,404 tonnes on September 29, demonstrating the increased material movement benefits realized from the commissioning of the first material pass during the quarter combined with the commencement of surface trucks operating in the twin incline. Total mine development was 2,477 metres. The operation continues to balance lateral development priorities between the completion of key underground projects, including prioritizing low equivalent lateral advance jumbo activities such as the Puma Ventilation Drive and the underground pastefill chamber.

- Total ore mined of 152,485 tonnes, the second highest on record, with mining activity across 13 levels, including the 1090, 1110, 1225, 1325, 1345, and 1365 levels at Kora, and the 1010, 1030, 1050, 1170, 1185, 1325, 1345 and 1385 levels at Judd – long hole open stoping performed to design.

Stage 3 Expansion – Significant Progress Made. Construction of Stage 3 Plant Complete, Commissioning Well-Advanced, First Gold Pour and First Concentrate Production on Track for First Half of Q4 2025

- Construction of the new 1.2 million tonnes-per-annum Stage 3 Expansion Process Plant is complete and was delivered under the capital expenditure budget, marking a major milestone for the construction team. Crushing, grinding and flotation circuits are now being commissioned with ore, with first gold pour, first gold-copper-silver concentrate production and completion of plant commissioning on schedule for the first half of Q4 2025. As at September 30, 2025, 90% of Stage 3 Expansion growth capital has either been spent or committed and remains on budget.

- During Q3, the major construction contracts were awarded for the pastefill plant. The surface tailings filtration plant detailed engineering and design is complete, early earthworks are complete and civil works have commenced. The surface storage facility near the underground mine is rapidly advancing, with site clearing complete, early earthworks underway, and detailed engineering nearly complete. The underground pastefill plant bulk excavations made significant progress during the quarter, and detailed engineering and design is nearly complete. Long-lead items for the various paste infrastructure projects are now arriving on site. Commissioning remains on schedule to commence mid-Q1 2026, with practical completion of commissioning of the pastefill circuit remaining on schedule for mid-2026.

- During the quarter, several key Stage 3 Expansion underground construction and operational excellence projects were completed or are approaching completion, including:

- Material Pass – Construction and commissioning completed in Q3, connecting the main mine via gravity to the highly productive twin incline haulage route. In late-Q3, multiple surface haulage daily records were delivered as noted above, driven by the commissioning of the material pass, combined with the commencement of surface haul trucks operating in the twin incline that transport material directly from underground to surface stockpiles, eliminating the need for rehandle. The next material pass is planned to commence development in Q4 and become operational in Q1 2026, enabling a dedicated pass for both ore and waste, respectively.

- Phase 2 Ventilation Upgrade – Development of two raisebored ventilation raises was completed in Q3, with the full ventilation upgrade planned for the second half of October. This upgrade is expected to deliver a +30% increase in primary mine airflow (150 m3/s to 200 m3/s), enabling two major productivity improvements: i) reduced re-entry times after blasting, and; ii) reduced blast initiation time with the introduction of a centralized blasting system which enables remote initiation from surface – these two combined improvements will enable firing twice a day (currently once a day).

- Phase 3 Ventilation Upgrade - Puma Ventilation Drive on schedule for Q4 completion and is now within 70m of surface breakthrough. Surface works are complete ahead of the breakthrough, and upon breakthrough, primary mine airflow is expected to increase to 250 m3/s, further reducing blast re-entry times and meeting the airflow requirements for the Stage 3 Expansion. Once complete, the vent circuit will be modified, so that the twin incline will operate under highly efficient one-way traffic flow that utilizes both inclines.

- Stage 4 Expansion Ventilation Upgrade – Installation of two x 2 MW variable speed drive fans is currently underway and scheduled for completion in Q4. Electrification is planned to be opportunistically completed in H1 2026 as it is not required for the Stage 3 Expansion.

- Decline-Incline Convergence Project connecting the Main Mine with the Twin Incline via internal ramp access – Significant progress was delivered in Q3 with 258 metres of advance achieved, leaving less than 370 metres of development required for completion. Upon completion scheduled for Q1 2026, this project is expected to deliver major operational efficiency improvements as the Main Mine will now also become accessible by the highly productive twin incline, and all mining fronts will be connected via an internal ramp, allowing for one-way traffic flow.

- Surface Tele-Remote Loader System – Completed in Q3, leveraging the underground fiber optic backbone (Wi-Fi), to enable the operation of underground loaders from surface. This system maximizes the available operating time over a 24-hour period by enabling tele-remote loading operations during shift change and re-entry. In late-Q3, the underground fleet was also fully integrated with onboard Wi-Fi capability to enable real-time data-collection for short interval control planning, productivity monitoring, and fleet diagnostics to further drive operational improvements.

- Primary Power Station – Phase 1, 8.8 MW of generation capacity was installed and commissioned in Q3. Phase 2 has significantly progressed with intended expansion to 15.2 MW. Long-lead orders have been placed and completion is planned for H1 2026. This will provide standby power during any unexpected outages from the local grid (hydroelectricity).

- Material Pass – Construction and commissioning completed in Q3, connecting the main mine via gravity to the highly productive twin incline haulage route. In late-Q3, multiple surface haulage daily records were delivered as noted above, driven by the commissioning of the material pass, combined with the commencement of surface haul trucks operating in the twin incline that transport material directly from underground to surface stockpiles, eliminating the need for rehandle. The next material pass is planned to commence development in Q4 and become operational in Q1 2026, enabling a dedicated pass for both ore and waste, respectively.

- Two new mining fronts have also been significantly developed, including five new sublevels in the Twin Incline mining front, and two new sublevels in the Lower Kora mining front, which will facilitate the ramp-up in long-hole stoping over the coming quarters for the Stage 3 Expansion.

Note (1): Gold equivalent production for Q3 2025 is calculated based on: gold $3,507 per ounce; silver $38.71 per ounce; and copper $4.49 per pound. Gold equivalent grade for Q3 incorporates realized recoveries of 95.0% for Au, 94.6% for Cu and 81.3% for Ag.

John Lewins, K92 Chief Executive Officer and Director, stated, “The third quarter marked another strong period of progress for K92 both in terms of production and continued execution of the Stage 3 Expansion. With the commissioning of the new 1.2 million tonnes-per-annum Stage 3 Expansion Process Plant nearing completion, this marks an exciting period in the Company’s history as K92 transitions into a Tier-1, mid-tier producer. Notably, ore has already been introduced into the crushing, grinding, and flotation circuits of the new process plant, keeping us firmly on track for practical completion of commissioning and the first gold pour and concentrate production in the first half of Q4 2025. Importantly, the team has built the process plant under-budget, representing a significant achievement.

We are also very pleased with the significant advancement we have made across a multitude of projects, de-risking the delivery of the Stage 3 Expansion and positioning the underground mine for Stage 4 and beyond. The recent string of daily records in total tonnes to surface moved (ore + waste) demonstrates that productivity and efficiency projects are now having a tangible impact on mine performance. Additionally, critical contracts were awarded, and construction works advanced, for all major pastefill infrastructure, with commissioning targeted to commence mid-Q1 2026. With 90% of Stage 3 growth capital already spent or committed, the expansion remains fully funded and on budget.

Having already delivered 80% of the lower end of our annual guidance within the first three quarters plus a commissioning stockpile of 4,893 oz AuEq at the end of Q3, we are well-positioned to achieve our 2025 production guidance.”

See Figure 1: Quarterly Production, Cash Cost and AISC Chart

See Figure 2: Gold and Copper Recoveries Chart

Table 1 – 2025 & 2024 Annual Production Data

| Q3 2024 | Q4 2024 | 2024 | Q1 2025 | Q2 2025 | Q3 2025 | ||

| Tonnes Processed | T | 104,992 | 96,614 | 427,821 | 103,449 | 130,337 | 137,172 |

| Feed Grade Au | g/t | 13.0 | 17.3 | 10.7 | 14.3 | 8.3 | 10.7 |

| Feed Grade Cu | % | 0.58% | 0.47% | 0.55% | 0.50% | 0.55% | 0.47% |

| Recovery (%) Au | % | 95.3% | 96.4% | 94.6% | 95.8% | 93.3% | 95.0% |

| Recovery (%) Cu | % | 95.1% | 94.7% | 94.1% | 95.1% | 94.9% | 94.6% |

| Metal in Conc & Doré Prod Au | oz | 41,702 | 51,371 | 139,123 | 45,735 | 32,375 | 42,244 |

| Metal in Conc Prod Cu | T | 580 | 435 | 2,235 | 518 | 697 | 600 |

| Metal in Conc Prod Ag | oz | 37,613 | 41,992 | 142,063 | 34,085 | 42,966 | 34,831 |

| Gold Equivalent Production | oz | 44,304 | 53,401 | 149,515 | 47,817 | 34,816 | 44,323 |

| Notes – | Gold equivalent for Q3 2025 is calculated based on: gold $3,507 per ounce; silver $38.71 per ounce; and copper $4.49 per pound. Gold equivalent for Q2 2025 is calculated based on: gold $3,299 per ounce; silver $33.41 per ounce; and copper $4.31 per pound. Gold equivalent for Q1 2025 is calculated based on: gold $2,855 per ounce; silver $31.73 per ounce; and copper $4.26 per pound Gold equivalent for Q4 2024 is calculated based on: gold $2,658 per ounce; silver $31.52 per ounce; and copper $4.25 per pound. Gold equivalent for Q3 2024 is calculated based on: gold $2,474 per ounce; silver $29.43 per ounce; and copper $4.17 per pound. |

Qualified Person

K92 Mine Chief Geologist, Andrew Kohler, PGeo, a qualified person under the meaning of Canadian National Instrument 43-101 – Standards of Disclosure for Mineral Projects, has reviewed and is responsible for the technical content of this news release. Data verification by Mr. Kohler includes significant time onsite reviewing drill core, face sampling, underground workings, and discussing work programs and results with geology and mining personnel.

Technical Report

The Updated DFS and mineral resource estimate for the Kainantu Gold Mine Project in Papua New Guinea is presented in a technical report, titled, “Independent Technical Report, Kainantu Gold Mine, Updated Definitive Feasibility Study, Kainantu Project, Papua New Guinea” dated March 21, 2025, with an effective date of January 1, 2024.

About K92

K92 Mining Inc. is engaged in the production of gold, copper and silver at the Kainantu Gold Mine in the Eastern Highlands province of Papua New Guinea, as well as exploration and development of mineral deposits in the immediate vicinity of the mine. The Company declared commercial production from Kainantu in February 2018, is in a strong financial position, and is working to become a Tier 1 mid-tier producer through ongoing plant expansions. A maiden resource estimate on the Blue Lake copper-gold porphyry project was completed in August 2022. K92 is operated by a team of mining company professionals with extensive international mine-building and operational experience.

On Behalf of the Company,

John Lewins, Chief Executive Officer and Director

For further information, please contact David Medilek, P.Eng., CFA, President and Chief Operating Officer at +1-604-416-4445

CAUTIONARY STATEMENT REGARDING FORWARD-LOOKING INFORMATION: This news release includes certain “forward-looking statements” under applicable Canadian securities legislation. Such forward-looking statements include, without limitation: (i) the results of the Kainantu Mine Definitive Feasibility Study, including the Stage 3 Expansion, a new standalone 1.2 million tonnes-per-annum process plant and supporting infrastructure; (ii) statements regarding the expansion of the mine and development of any of the deposits; (iii) the Kainantu Stage 4 Expansion, operating two standalone process plants, larger surface infrastructure and mining throughputs; and (iv) the potential extended life of the Kainantu Mine.

All statements in this news release that address events or developments that we expect to occur in the future are forward-looking statements. Forward-looking statements are statements that are not historical facts and are generally, although not always, identified by words such as “expect”, “plan”, “anticipate”, “project”, “target”, “potential”, “schedule”, “forecast”, “budget”, “estimate”, “intend” or “believe” and similar expressions or their negative connotations, or that events or conditions “will”, “would”, “may”, “could”, “should” or “might” occur. All such forward-looking statements are based on the opinions and estimates of management as of the date such statements are made. Forward-looking statements are necessarily based on estimates and assumptions that are inherently subject to known and unknown risks, uncertainties and other factors, many of which are beyond our ability to control, that may cause our actual results, level of activity, performance or achievements to be materially different from those expressed or implied by such forward-looking information. Such factors include, without limitation, Public Health Crises, including the epidemic or pandemic viruses; changes in the price of gold, silver, copper and other metals in the world markets; fluctuations in the price and availability of infrastructure and energy and other commodities; fluctuations in foreign currency exchange rates; volatility in price of our common shares; inherent risks associated with the mining industry, including problems related to weather and climate in remote areas in which certain of the Company’s operations are located; failure to achieve production, cost and other estimates; risks and uncertainties associated with exploration and development; uncertainties relating to estimates of mineral resources including uncertainty that mineral resources may never be converted into mineral reserves; the Company’s ability to carry on current and future operations, including development and exploration activities at the Arakompa, Kora, Judd and other projects; the timing, extent, duration and economic viability of such operations, including any mineral resources or reserves identified thereby; the accuracy and reliability of estimates, projections, forecasts, studies and assessments; the Company’s ability to meet or achieve estimates, projections and forecasts; the availability and cost of inputs; the availability and costs of achieving the Stage 3 Expansion or the Stage 4 Expansion; the ability of the Company to achieve the inputs the price and market for outputs, including gold, silver and copper; failures of information systems or information security threats; political, economic and other risks associated with the Company’s foreign operations; geopolitical events and other uncertainties, such as the conflicts in Ukraine, Israel and Palestine; compliance with various laws and regulatory requirements to which the Company is subject to, including taxation; the ability to obtain timely financing on reasonable terms when required; the current and future social, economic and political conditions, including relationship with the communities in Papua New Guinea and other jurisdictions it operates; other assumptions and factors generally associated with the mining industry; and the risks, uncertainties and other factors referred to in the Company’s Annual Information Form under the heading “Risk Factors”.

Estimates of mineral resources are also forward-looking statements because they constitute projections, based on certain estimates and assumptions, regarding the amount of minerals that may be encountered in the future and/or the anticipated economics of production. The estimation of mineral resources and mineral reserves is inherently uncertain and involves subjective judgments about many relevant factors. Mineral resources that are not mineral reserves do not have demonstrated economic viability. The accuracy of any such estimates is a function of the quantity and quality of available data, and of the assumptions made and judgments used in engineering and geological interpretation, Forward-looking statements are not a guarantee of future performance, and actual results and future events could materially differ from those anticipated in such statements. Although we have attempted to identify important factors that could cause actual results to differ materially from those contained in the forward-looking statements, there may be other factors that cause actual results to differ materially from those that are anticipated, estimated, or intended. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking statements. The Company disclaims any intention or obligation to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law.

Figure 1: Quarterly Production, Co-Product Cash Cost and Co-Product AISC Chart

Figure 2: Gold and Copper Recoveries Chart

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/72bbafe4-1519-4e66-8f75-77d06748b04f

https://www.globenewswire.com/NewsRoom/AttachmentNg/1ce69a80-051d-4ed1-b931-2ceaced93d64